FDS-B737NG-PRO-MX-TQ

NEW FOR 2021!

AS REAL AS IT GETS

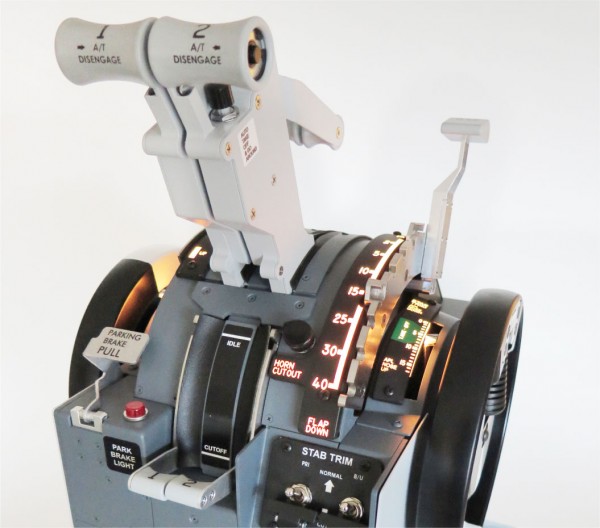

Every component of a simulator has the power to enhance or diminish the flight experience, and nothing is more true for a key piece like a Throttle Quadrant. Our engineers meticulously worked out the cosmetics and mechanics of the FDS-B737NG-PRO-MX-TQ to ensure it delivers near perfect to the real aircraft. All shapes, contours, and intricacies of the real unit are portrayed in this unit.

The Fully Motorized Levers feature ultra-smooth movement across their full range of motion, the Trim Wheels are motorized and feature variable speeds and retractable handle for manual trim adjustment, and the flap lever features accurate flap detents and tactile feel. Additionally, the backlighting is highly consistent thanks to our proprietary full-scale IBL panel set.

To ensure fast communication between devices we equipped the FDS-B737NG-PRO-MX-TQ with a high speed Ethernet Interface. This, coupled with our proprietary “Closed Loop” design, means we can deliver high levels of accuracy on the functionality side. As real as it gets and 100% tactile.

COMMERCIAL GRADE ENGINEERING & PRODUCTION

With our presence well established in the commercial sector, FDS product development has been fine tuned to meet the stringent demands of that market. As such, the goal to perfectly replicate the real aircraft device is only the beginning. High level of reliability of all the components is now more important than ever, and we achieve this by way of clever engineering and highly selective parts usage.

No shortcuts are taken. In addition to the 120 man-hours required to produce each throttle unit, every piece is put through a 48 hour "Run" cycle as part of the Quality Control Check prior to packaging and shipment.

FULLY MOTORIZED*

*B737MAX version shown.

FEATURES

- Fully Motorized Levers

- Closed Loop Control to deliver realistic action

- Auto Throttle Override

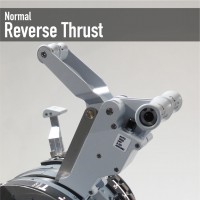

- Variable and Full Reverse Thrust Levers

- Motorized/Auto Lifting Speed Brake Lever

- Motorized Trim Wheels with Variable Speeds

- Manual Trim Capability with Retractable Trim Wheel Handle

- Solenoid Driven Parking Brake

- Compound Curve Trim Indicator Panels

- Full Scale IBL Panel Set

- Switchable IBL Interface (always on or external dimmer)

- Accurate Flap Detents (with proper guarded positions)

- High quality engraved knobs

- Ethernet Interface

- Wiring tunnel for safe cable routing

- High quality long life control electronics (10M cycles, exceeding the life of most hall effect pots!)

- High quality Aluminum and Stainless Steel construction

- Dual Voltage (110/240v) Power Supply with Auto Switching

COMPATIBILITY

Software determines the level of overall functionality. The following avionics software packages are functional or in test:

- SIM AVIONICS - READY!

- ProSim - Nearing Completion

- X-Plane Zibo - On Our Radar!

AVAILABILITY

This is a commercial level product. As such, production can be limited. Please talk to us about your specific device and your requirements.